Continual ISO-Based Improvement

Every three years, STC hosts an external audit to recertify our Quality Management System to ISO 9001 standards. The external audit for 2021 was recently completed, and STC once again successfully met the requirements for recertification.

One notable aspect of adherence to ISO standards is the commitment to continuously improve company performance. This continual improvement has been part of the STC quality process since becoming ISO certified in 1999. Improvement can be measured in any number of quality-system metrics, and one of the metrics STC tracks is the customer-return rate.

During the first few years of ISO certification, customer-return rates were quite a bit higher than they are now. In 2002, we recorded 25 RMAs (returned material authorization). However, that number dropped to 3 in 2020, and the RMA number for 2021 stands at 2.

What are the reasons for the dramatic drop in customer returns? According to Angie Calkin, who serves as STC Vice President of Operations, a large part of the reason is due to the year-by-year improvements required by ISO.

“ISO has formalized our processes and, as years go by, people get acclimated to the process and end up catching mistakes long before they go out the door. Our largest RMA numbers occurred prior to ISO certification, and there’s been a steady decrease over the years.”

Calkin has also found that many of quality issues they catch now are not electrical problems, but rather mechanical or visual miscues that can shorten the working life of a part or component.

“Because we perform 100-percent testing, it’s very rare that we have an actual electrical issue,” Calkin says. “It’s typically a dimensional issue or perhaps shipping damage.”

At that point, dimensions, packaging, and freight carriers become an area of focus for the internal ISO audits, which take place every year. Calkin also gives full credit to the STC production staff.

“We spend the time needed to train our production team, and they catch even minor issues that just have the potential to lead to returned material. Our Shipping Manager helps a lot too, by looking at the documentation before shipping and recognizing potential issues.”

Calkin continues, “You can cover up poor workmanship that will affect the life of a part, but the people on our production team are able to build the parts correctly right from the start.”

STC Certified as HUBZone Business

The US Small Business Administration has approved STC, Inc as a certified HUBZone small business concern. As such, STC is now eligible for HUBZone benefits, which provide enhanced federal contracting opportunities for qualified small businesses located within HUBZones (historically underutilized business zones).

The approval of STC follows recent changes to the HUBZone program, which has seen some expansion into rural areas that were not previously served by the program.

According to STC President Brad Cross, the HUBZone certification offers real benefits for STC, which provides electronics manufacturing services for a wide variety of applications, including aerospace, defense, and environmental industries.

“The HUBZone program allows for more direct government contracting opportunities, and it also allows us to hire people from within our community. So qualified individuals have an opportunity to work in technology without leaving the area,” says Cross.

“Also, with broadband connectivity, rural areas aren’t subject to the same disadvantages they had to overcome in the past,” Cross continues. “We’ve found that we can participate in integrated technology development where speed and responsiveness are really an advantage for us.”

With the HUBZone certification, Cross also sees increased opportunities to continue building partnerships with industry-leading companies as STC promotes both economic and technological development.

“We’re proud of the many partnerships we’ve created with our customers, and we look forward to forming new partnerships as we pursue the opportunities set aside for HUBZone communities,” Cross said.

Open Position: Electronic Technician

STC, Inc., a manufacturer of transformers & PCB assemblies for a variety of industries, including Aerospace, Military, Broadcasting, and Traffic Management is seeking candidates for an Electronic Technician.

For a full list of job requirements and qualifications, as well as information about how to apply, please see the Careers at STC page.

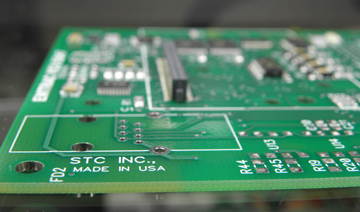

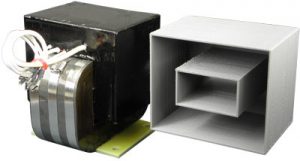

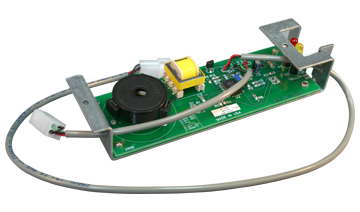

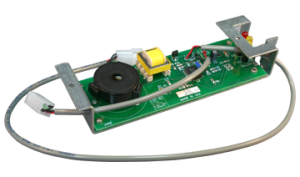

PCBs with Custom Magnetics

At first contact, many potential customers may be unaware that we not only manufacture custom transformers and inductors but that we also provide electronic manufacturing services (EMS) for a wide range of industries and applications.

For many customers, STC provides both transformer manufacturing and printed-circuit assembly. These combined services allow STC customers to save time and money. Here’s how:

- Reduced Shipping Damage: With our PCB assemblies, weighty and awkward transformers with fragile connection pins are delivered already mounted to circuit-board assemblies, which reduces the potential for damage during shipment.

- Reduced Shipping & Handling Costs: A single supplier for transformers and PCB assemblies dramatically reduces the number of containers, which results in lower overall shipping costs.

- Inventory Imbalance: STC customers avoid having too many of a particular part (for example transformers) because the transformers arrive as part of the circuit-board assembly. This alone helps reduce unnecessary inventory.

- Quality Control: Because we provide both coil manufacturing and PCB assembly, STC customers are able to simplify their own manufacturing process. STC is also ISO:9001 certified with 100-percent testing available.

We at STC work hard to deliver quality products while meeting delivery deadlines. How can we help your business? Please feel free to let us know.

Calkin’s 30-Year Milestone

“When I think about the biggest moments of my career at STC,” says Angie Calkin, “I would probably say the Nighthawk production line, our becoming ISO 9001 certified, and then my promotion to Vice President of Operations.”

Calkin has seen many changes during her 30 years at STC, but these moments mark three significant shifts in her mind.

The Nighthawk production line fulfilled orders for transformers used in the Nighthawk brand of carbon monoxide detectors. At that point in the 1990s, the Nighthawk orders were the largest ever placed with STC.

“At that time, I was involved with Testing, Quality, and Electronics Production. Then I became Project Manager for the Nighthawk line—which shipped between 2,000 and 4,000 transformers per day. That is a lot compared to what we had been producing. We had three shifts running to meet the orders. We purchased new winding equipment. We hired new employees, so we were interviewing, hiring, and training. It was both very exciting and stressful.”

At the time, Calkin felt she lacked the experience for the wide range of abilities the job required, but she learned quickly.

“You can imagine the complexity to ship that many parts each day, from having the material in place, to handling employee issues, to dealing with machine breakdowns, and then the logistics for shipping, Calkin says with a laugh. “I can’t tell you how many times [husband] Jim and I made the 40-mile trip to the shipping center to drop off additional parts to be shipped.”

Angie started at STC as a production worker alternating between Electronics assembly and Magnetics (transformers). In 1989, STC moved across town to its current location. The move took a couple of months to complete, and Angie was the first one to relocate to the much larger facility. As a result, she worked alone for a month or two until the move was complete.

“Quality testing was an ongoing part of my responsibilities, but it got to the point there were projects we knew we couldn’t bid because we weren’t ISO certified,” Angie says. “We worked hard to become ISO 9001 certified. In addition to many other tasks, we wrote Procedure and Quality manuals, which we update as needed to maintain our ISO certification.”

After 18 years at STC, Angie was promoted to Vice President of Operations, and there was no question about the first priority to be addressed in her new position.

“I know when I took over, we were way behind on our production schedule, and it was a real challenge to catch up on,” says Angie. “It was at that point that I started communicating more frequently with customers—and you learn a lot of important things doing that. I started interacting with so many facets of our customer’s businesses, so you learn much more about what they require and why they require it.

Angie is pleased with the current state of STC.

“I think the company’s done well. I credit [STC President] Brad Cross for that, his leadership. The work we do now is a lot more high reliability, and it’s taken time to build up to that.”

When asked about Angie’s contributions to STC, Cross is quick to point out the benefits gained from her hard work and eye for detail.

“Angie’s high standards for order execution and quality impacts our entire organization.”

Thanks for your hard work and leadership during your time at STC Angie—and best wishes for the next 30 years!

Vaughn Reflects on 30 Years at STC

During the year 2018, three STC employees celebrate their 30-year anniversary with the company. Design Engineer Les Vaughn marks his anniversary today, and it also offers a chance for him to reflect on some of the many memories of his time at STC.

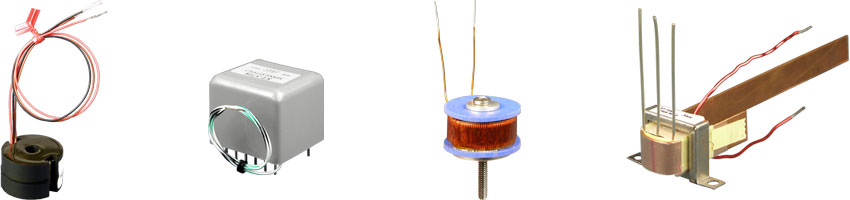

Vaughn works primarily in Magnetics and has designed several hundred transformers for STC customers. His transformer designs can be found in everything from large and small aircraft, broadcast towers, military equipment, medical devices, manufacturing machinery, common household appliances, and much more.

When Les started at STC, his first role was in testing.

“At that time, testing involved hooking up leads and checking meters—rather than using the advanced automated testing equipment we have now,” Vaughn says. “I worked closely with the plant manager at that time, Bob Simpson, who was very helpful, and I eventually transitioned over time to design engineering.”

Les was certainly qualified for that role, in both education and work experience. Prior to starting at STC, Les worked for about 12 years in broadcast engineering, and with a combination of electronics and mechanical work during a short stint at a printing press in Mt. Vernon, Illinois.

“Some of my favorite types of magnetics projects are those for high-voltage transformers,” Vaughn says. “One project we did for a university was for a kind of high-voltage plasma application. Those projects are fun because you get a chance to be involved with cutting-edge technology—and, of course, you need to test those designs to see how big of an arc it will put out,” Vaughn adds with a laugh.

“We have a lot of experience, and our manufacturing capabilities really work to our advantage. Those things make a big difference when it comes to high-voltage transformers, not to mention instrument transformers, autotransformers, three-phase transformers. You get the idea.”

STC President Brad Cross also appreciates Vaughn’s expertise.

“Les is interested in technology, not only as a profession, but as an avocation or hobby, which is really beneficial.” Cross says. “He cares about his customers and finding the right solutions to fit their needs.

“Because of his expertise, he’s able to steer customers toward a design that not only meets their requirements, but is also economical and available within a reasonable amount of time. He’s a tremendous resource from that perspective too.”

Thanks for offering your expertise to those of us at STC and to our customers Les. Best wishes for the next 30 years!

Linda Shaw Celebrates 30 Years

Having started work at STC in June of 1988, Production Supervisor Linda Shaw celebrates 30 years at STC this week.

“When I started at STC, I had five kids in grade school. Now I have four grandkids who have graduated from high school,” Shaw said.

Linda started work at STC in transformer production, which is where she has spent her entire career in positions of increased responsibility. Prior to coming to STC, she spent about three years working at a shoe factory. While the type of production work at STC was much different, Linda says there were many other elements that carried over.

“Making shoes is quite a bit different than making transformers, but there were many things I was able to bring with me to STC,” Shaw said. “Being on time, being dependable, quality as an expectation, respecting your fellow workers, and respecting your customers, those are all very important no matter where you work.”

Linda was mentored early on by the Plant Manager Bob Simpson. During this time, she learned nearly every single aspect to building the many different custom transformers produced at STC. After about six years, Linda became a Team Leader, responsible for training her production group on the various transformer lines being built by the team.

“Linda was kind of like the lead for a long time anyway,” says Vice President of Operations Angie Calkin. “She had the personality and aptitude to understand the process—and she had a good work ethic.”

Linda was named Production Supervisor two or three years later, a job she’s held ever since. However, despite her experience and leadership roles, Linda didn’t necessarily feel ready for the additional responsibilities.

“I didn’t really feel qualified. I took the responsibility and learned as I went,” Shaw said. “I wasn’t outgoing so I had to learn how to open up and how to give orders. I learned to delegate too, so the work could be shared by the whole team.”

Has production work changed in the past 30 years?

“Things are much different,” says Shaw. “Technology has made things easier and faster, things like automatic winders, solder machines, and testing equipment.”

Linda’s not the type of person you’d guess has been at STC for 30 years though. She’s quick to smile and laugh, a little feisty, and still very much focused on getting the job done quickly and with quality.

Regarding her time at the shoe factory before coming to STC, Linda reflected on the values that have served her and her coworkers well.

“I was basically taught the same things there that I try to teach here. If you were buying the product, what would you expect—quality. It’s the golden rule really.”

STC President Brad Cross finds it easy to express his appreciation.

“Linda’s the kind of staff member every manager wants on their team. Her skills and leadership are second to none.”

Thanks for your hard work and friendship Linda, and best wishes for the next 30 years!

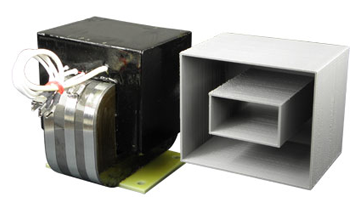

3D Printing Benefits STC Customers

For a number of years, STC engineers have utilized 3D printing in a variety of ways to cut down on both production costs and lead times. In some cases, 3D printing can save thousands of dollars in tooling costs during the design phase. In other cases, the 3D-printed assembly components can be used in the final design and no further tooling charges are necessary.

Design engineer Les Vaughn says one of the best times to benefit from 3D printing is during initial product development.

“As an example, take an encapsulation cup for a transformer,” says Vaughn. “These cups are used as a mold for the epoxy that actually encapsulates the wires. If the cup size we need for a custom design isn’t available as a stock item, it’s faster and less expensive to 3D print the cup than having them fabricated and shipped to us.”

3D printing is also utilized for coil winding forms. The form provides a rigid surface around which wire is wound. In many cases, the form is made out of square tubes of Mylar or craft paper. However, specialty designs may require a custom form, and 3D printing offers a quick and cost-effective method for building that form.

STC engineers also utilize 3D printing for electronics design and assembly. One particular STC product consists of circuit boards mounted to a face plate with interface controls. While looking for alternate brackets for mounting the PC boards to the face plate, CAD Technician Leslie Hopkins was able to quickly design and 3D print a face plate and PC boards with relocated mounting holes. This enabled her to easily test a number of different bracket styles.

Hopkins feels 3D-printing offers the best opportunity to test the final assembly and fit.

“It gave me a chance to test some different types of brackets to make sure they were secure, and to then make sure the assembled model fit in the cabinet rack where the final product is installed,” Hopkins said.

There are still other applications where 3D printing has been beneficial, such as in making fixtures to assist in electronics and magnetics assembly. However, the main benefits of each of the various 3D-printing applications remain the same.

“It comes down to speed, cutting down on lead times, more design iterations so we can design toward the highest possible quality,” says STC President Brad Cross. “And, of course, when you cut down on time, you also reduce cost.”

New Product Development with STC

In the 30-plus years STC has been in business, many of our customers have come into contact with us during the development phase for a new product.

In some cases, customers are able to submit detailed specifications, including information such as volt-ampere requirements, available dimensions (footprint or envelope), ambient operating temperature, and many other product requirements.

However, it’s perhaps more common for customers to be unable to submit detailed specifications, which presents an opportunity to consider the many available design options for a given project. For cases like this, we often discuss the following specifications (in addition to other requirements):

- Maximum Heat Rise

- Insulation Class

- Maximum Excitation Current or “Surge Current”

- Duty Cycle

- Dielectric Strength

- Leakage Inductance

- Interwinding Capacitance

…one particular safety certification may be more suitable—and beneficial—than another, and customers must also consider the varying cost and potential benefits for the lab testing that goes along with these certifications.

Then there are other considerations, like safety certifications (such as UL, CE, ETL, and so forth). These certifications are assigned after lab testing to confirm the component meets specific safety requirements. After successful testing, the corresponding certification mark is typically applied and displayed on the component.

However, one particular safety certification may be more suitable—and beneficial—than another, and customers must also consider the varying cost and potential benefits for the lab testing that goes along with these certifications.

There are a number of factors to evaluate when considering available safety certifications, and STC design engineers know which questions to ask to determine the appropriate certification for each new product.

STC’s wide range of capabilities enable us to design both at the component level—as well as the circuitry around that component. Our magnetics capabilities enable us to integrate the right power-supply transformer, and our EMS capabilities enable us to work that power supply into the final electronics assembly. Need a unique enclosure for a box-build assembly? We also have 3D-modeling and printing capabilities, which are useful during the prototype phase to help a customer arrive at a precise case or cabinet design.

Product development is our specialty—and we look forward to working with you on your upcoming product. Contact us to see how we can help you.

Trends in US Contract Manufacturing

For the past number of years, the topic of “re-shoring” has been addressed in various manufacturing-industry publications, as well as in the general media. Re-shoring is the term used to describe companies moving segments of production or services back to the United States after having previously moved that work to off-shore locations.

However, in practice, moves to US manufacturing have primarily been the result of specific scenarios, according to STC President Brad Cross.

“There are specific situations where we have a distinct competitive edge, for example with government projects that require a certain percentage of the assemblies to be manufactured in the US,” says Cross. “But in addition to those types of projects, we also have an edge when companies must deal with defective parts that have entered their supply chain”

In these cases, component defects aren’t discovered until they’ve reached US plants. And by that time, the defective parts are already installed in assembled products, and additional defective parts are likely sitting in multiple shipping containers in various stages of the supply chain.

“When these kinds of problems arise, we often beat the overall costs that result from these types of overseas manufacturing problems,” Cross says. “While STC regularly outperforms other manufacturers in quality and lead time, these common types of situations give us yet another advantage.”

Another issue that drives re-shoring is source traceability, which has become a much bigger area of interest since the Dodd-Frank bill was signed in 2010. To address the humanitarian crisis in Central Africa, Section 1502 of this law requires that companies disclose whether any minerals used in their manufacturing (such as tin, tungsten, and gold) originate from the Democratic Republic of the Congo or any adjoining countries.

Angie Calkin, who serves at the STC Quality Manager, says this requirement gives US companies like STC an edge where source traceability is a concern.

“In order to be compliant with this law, we must carefully select and monitor US vendors who have already verified their own sources, and that’s an advantage for a company like ours since we have longstanding relationships with so many of our vendors.” Calkin says. “For overseas manufacturers, source traceability is rarely a requirement so when US companies try to require it of their suppliers, it becomes another layer of complexity that is almost impossible to get through.”

According to Cross, being familiar with your product sources reduces reliability issues that can result from another large area of concern, which is component counterfeiting.

“Component counterfeiting is something that has gone on for many years and seems to have increased during the last 20 years, and the key problem with counterfeiting is reliability,” Cross says.

Counterfeit components look identical to the name-brand models they copy, with fake date codes, product markings, and even stamped copies of the brand logo.

Statistics provided by the US Customs and Border Protection agency indicate that China/Hong Kong is by far the largest source of counterfeit goods that arrive in the United States, followed by India, Singapore, and a number of other countries. (https://www.cbp.gov/trade/priority-issues/ipr/statistics)

“It’s costly to test for these inferior components because the testing is time consuming and the tests are often destructive,” Cross added.

“For example, the use of inferior insulation or construction techniques in magnetics drastically reduce a transformer lifespan. Years ago, one of our customers found a Chinese source that was able to provide similar high-voltage transformers at about half our cost, so they began buying the import transformers. The resulting assembled products passed factory testing but ended up consistently failing in customer use far short of their warranties. We resumed supplying their transformers not long after that.”

Cross also claims the counterfeiting problem is even more prevalent in the electronics-component market, though the resulting issues are very similar.

“Semiconductors that would otherwise be expected to last for 20 years also pass testing after installation on the assembled product, but then often fail within a few months, leading to considerable warranty costs for the brand manufacturer.”