Calkin’s 30-Year Milestone

“When I think about the biggest moments of my career at STC,” says Angie Calkin, “I would probably say the Nighthawk production line, our becoming ISO 9001 certified, and then my promotion to Vice President of Operations.”

Calkin has seen many changes during her 30 years at STC, but these moments mark three significant shifts in her mind.

The Nighthawk production line fulfilled orders for transformers used in the Nighthawk brand of carbon monoxide detectors. At that point in the 1990s, the Nighthawk orders were the largest ever placed with STC.

“At that time, I was involved with Testing, Quality, and Electronics Production. Then I became Project Manager for the Nighthawk line—which shipped between 2,000 and 4,000 transformers per day. That is a lot compared to what we had been producing. We had three shifts running to meet the orders. We purchased new winding equipment. We hired new employees, so we were interviewing, hiring, and training. It was both very exciting and stressful.”

At the time, Calkin felt she lacked the experience for the wide range of abilities the job required, but she learned quickly.

“You can imagine the complexity to ship that many parts each day, from having the material in place, to handling employee issues, to dealing with machine breakdowns, and then the logistics for shipping, Calkin says with a laugh. “I can’t tell you how many times [husband] Jim and I made the 40-mile trip to the shipping center to drop off additional parts to be shipped.”

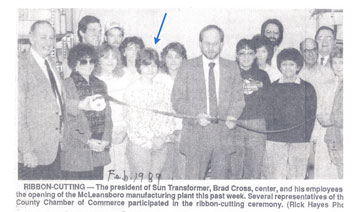

Angie started at STC as a production worker alternating between Electronics assembly and Magnetics (transformers). In 1989, STC moved across town to its current location. The move took a couple of months to complete, and Angie was the first one to relocate to the much larger facility. As a result, she worked alone for a month or two until the move was complete.

“Quality testing was an ongoing part of my responsibilities, but it got to the point there were projects we knew we couldn’t bid because we weren’t ISO certified,” Angie says. “We worked hard to become ISO 9001 certified. In addition to many other tasks, we wrote Procedure and Quality manuals, which we update as needed to maintain our ISO certification.”

After 18 years at STC, Angie was promoted to Vice President of Operations, and there was no question about the first priority to be addressed in her new position.

“I know when I took over, we were way behind on our production schedule, and it was a real challenge to catch up on,” says Angie. “It was at that point that I started communicating more frequently with customers—and you learn a lot of important things doing that. I started interacting with so many facets of our customer’s businesses, so you learn much more about what they require and why they require it.

Angie is pleased with the current state of STC.

“I think the company’s done well. I credit [STC President] Brad Cross for that, his leadership. The work we do now is a lot more high reliability, and it’s taken time to build up to that.”

When asked about Angie’s contributions to STC, Cross is quick to point out the benefits gained from her hard work and eye for detail.

“Angie’s high standards for order execution and quality impacts our entire organization.”

Thanks for your hard work and leadership during your time at STC Angie—and best wishes for the next 30 years!

Vaughn Reflects on 30 Years at STC

During the year 2018, three STC employees celebrate their 30-year anniversary with the company. Design Engineer Les Vaughn marks his anniversary today, and it also offers a chance for him to reflect on some of the many memories of his time at STC.

Vaughn works primarily in Magnetics and has designed several hundred transformers for STC customers. His transformer designs can be found in everything from large and small aircraft, broadcast towers, military equipment, medical devices, manufacturing machinery, common household appliances, and much more.

When Les started at STC, his first role was in testing.

“At that time, testing involved hooking up leads and checking meters—rather than using the advanced automated testing equipment we have now,” Vaughn says. “I worked closely with the plant manager at that time, Bob Simpson, who was very helpful, and I eventually transitioned over time to design engineering.”

Les was certainly qualified for that role, in both education and work experience. Prior to starting at STC, Les worked for about 12 years in broadcast engineering, and with a combination of electronics and mechanical work during a short stint at a printing press in Mt. Vernon, Illinois.

“Some of my favorite types of magnetics projects are those for high-voltage transformers,” Vaughn says. “One project we did for a university was for a kind of high-voltage plasma application. Those projects are fun because you get a chance to be involved with cutting-edge technology—and, of course, you need to test those designs to see how big of an arc it will put out,” Vaughn adds with a laugh.

“We have a lot of experience, and our manufacturing capabilities really work to our advantage. Those things make a big difference when it comes to high-voltage transformers, not to mention instrument transformers, autotransformers, three-phase transformers. You get the idea.”

STC President Brad Cross also appreciates Vaughn’s expertise.

“Les is interested in technology, not only as a profession, but as an avocation or hobby, which is really beneficial.” Cross says. “He cares about his customers and finding the right solutions to fit their needs.

“Because of his expertise, he’s able to steer customers toward a design that not only meets their requirements, but is also economical and available within a reasonable amount of time. He’s a tremendous resource from that perspective too.”

Thanks for offering your expertise to those of us at STC and to our customers Les. Best wishes for the next 30 years!

Linda Shaw Celebrates 30 Years

Having started work at STC in June of 1988, Production Supervisor Linda Shaw celebrates 30 years at STC this week.

“When I started at STC, I had five kids in grade school. Now I have four grandkids who have graduated from high school,” Shaw said.

Linda started work at STC in transformer production, which is where she has spent her entire career in positions of increased responsibility. Prior to coming to STC, she spent about three years working at a shoe factory. While the type of production work at STC was much different, Linda says there were many other elements that carried over.

“Making shoes is quite a bit different than making transformers, but there were many things I was able to bring with me to STC,” Shaw said. “Being on time, being dependable, quality as an expectation, respecting your fellow workers, and respecting your customers, those are all very important no matter where you work.”

Linda was mentored early on by the Plant Manager Bob Simpson. During this time, she learned nearly every single aspect to building the many different custom transformers produced at STC. After about six years, Linda became a Team Leader, responsible for training her production group on the various transformer lines being built by the team.

“Linda was kind of like the lead for a long time anyway,” says Vice President of Operations Angie Calkin. “She had the personality and aptitude to understand the process—and she had a good work ethic.”

Linda was named Production Supervisor two or three years later, a job she’s held ever since. However, despite her experience and leadership roles, Linda didn’t necessarily feel ready for the additional responsibilities.

“I didn’t really feel qualified. I took the responsibility and learned as I went,” Shaw said. “I wasn’t outgoing so I had to learn how to open up and how to give orders. I learned to delegate too, so the work could be shared by the whole team.”

Has production work changed in the past 30 years?

“Things are much different,” says Shaw. “Technology has made things easier and faster, things like automatic winders, solder machines, and testing equipment.”

Linda’s not the type of person you’d guess has been at STC for 30 years though. She’s quick to smile and laugh, a little feisty, and still very much focused on getting the job done quickly and with quality.

Regarding her time at the shoe factory before coming to STC, Linda reflected on the values that have served her and her coworkers well.

“I was basically taught the same things there that I try to teach here. If you were buying the product, what would you expect—quality. It’s the golden rule really.”

STC President Brad Cross finds it easy to express his appreciation.

“Linda’s the kind of staff member every manager wants on their team. Her skills and leadership are second to none.”

Thanks for your hard work and friendship Linda, and best wishes for the next 30 years!

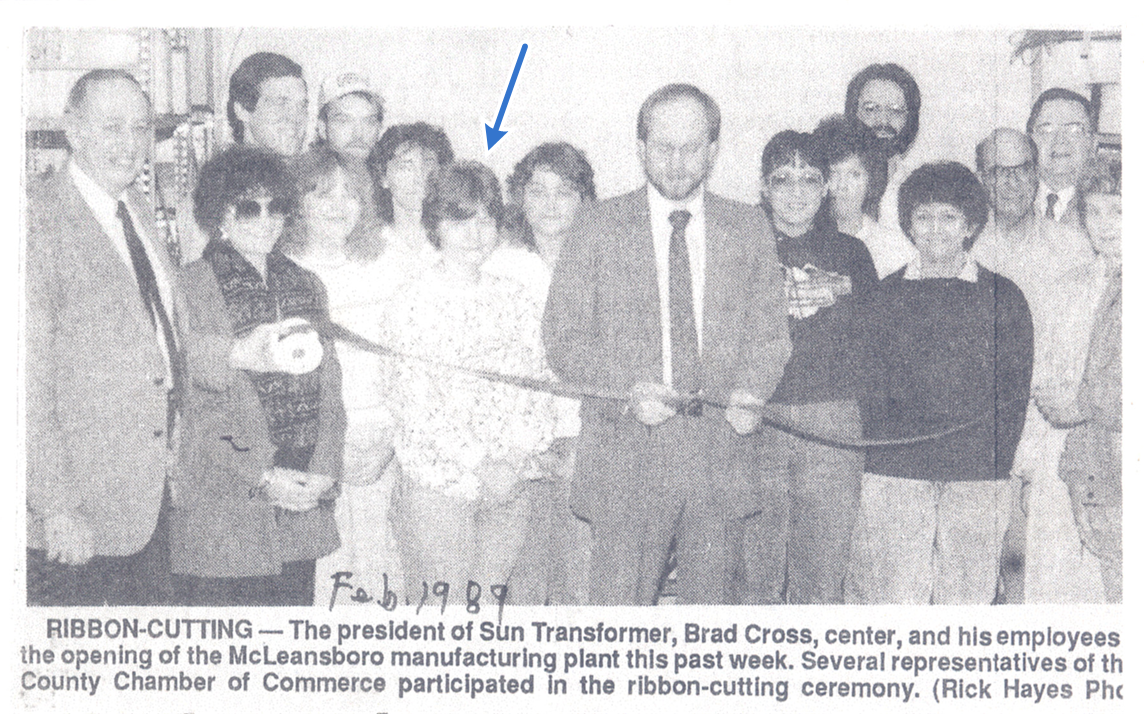

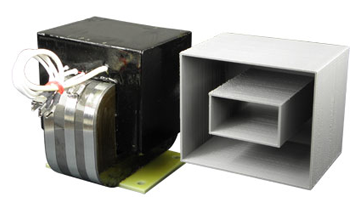

3D Printing Benefits STC Customers

For a number of years, STC engineers have utilized 3D printing in a variety of ways to cut down on both production costs and lead times. In some cases, 3D printing can save thousands of dollars in tooling costs during the design phase. In other cases, the 3D-printed assembly components can be used in the final design and no further tooling charges are necessary.

Design engineer Les Vaughn says one of the best times to benefit from 3D printing is during initial product development.

“As an example, take an encapsulation cup for a transformer,” says Vaughn. “These cups are used as a mold for the epoxy that actually encapsulates the wires. If the cup size we need for a custom design isn’t available as a stock item, it’s faster and less expensive to 3D print the cup than having them fabricated and shipped to us.”

3D printing is also utilized for coil winding forms. The form provides a rigid surface around which wire is wound. In many cases, the form is made out of square tubes of Mylar or craft paper. However, specialty designs may require a custom form, and 3D printing offers a quick and cost-effective method for building that form.

STC engineers also utilize 3D printing for electronics design and assembly. One particular STC product consists of circuit boards mounted to a face plate with interface controls. While looking for alternate brackets for mounting the PC boards to the face plate, CAD Technician Leslie Hopkins was able to quickly design and 3D print a face plate and PC boards with relocated mounting holes. This enabled her to easily test a number of different bracket styles.

Hopkins feels 3D-printing offers the best opportunity to test the final assembly and fit.

“It gave me a chance to test some different types of brackets to make sure they were secure, and to then make sure the assembled model fit in the cabinet rack where the final product is installed,” Hopkins said.

There are still other applications where 3D printing has been beneficial, such as in making fixtures to assist in electronics and magnetics assembly. However, the main benefits of each of the various 3D-printing applications remain the same.

“It comes down to speed, cutting down on lead times, more design iterations so we can design toward the highest possible quality,” says STC President Brad Cross. “And, of course, when you cut down on time, you also reduce cost.”