Quality Partnerships

As a manufacturer of high-reliability magnetics and electronics assemblies, STC often works in partnership with clients to ensure that our products meet the unique quality requirements for each specific project.

These requirements are in addition to STC’s existing quality and production certifications, and they are created to supplement quality procedures and help maintain error-free use in the field. They also include periodic assessments and audits performed by client project managers during onsite visits.

One recent onsite visit was from Warren Witmer, who works as Supplier Development Project Manager for Honeywell International. Witmer, who is also a Six Sigma Black Belt as well as a Quality Control Engineer, visits STC throughout the year to conduct inspections, process reviews, and carry out other quality-assurance related tasks.

During his visits, Witmer works closely with STC Quality Manager Angie Calkin, who is responsible for implementing and overseeing the various quality programs at STC. According to Calkin, Witmer’s onsite visits add value to STC’s quality programs.

“We generally see Warren several times a year. His visits include supplier-development education, supplier assessments, and occasionally he performs field quality engineer duties such as first-article inspection and self release audits,” Calkin says. “I always enjoy Warren’s visits. They are generally productive and informative.”

When Witmer goes back to Honeywell, Calkin says, the cooperative work continues.

“Warren plays an essential role in our relationship with Honeywell. He is our go-to guy when an issue arises and we don’t know who in the organization to reach out to. If Warren can’t resolve the issue himself, he points us to appropriate person.”

These types of partnerships are not uncommon when it comes to the complex projects, and STC staff members are accustomed to making them work—for both STC as well as for our partners.

STC Celebrates 30 Years

STC is celebrating their 30th anniversary as a manufacturer of high-reliability electronics and transformers. As an ISO 9001 certified business, STC provides product design, development, manufacturing, assembly, testing, and sustainment services.

When asked to comment on why Sun Transformer has been able to grow and succeed for so many years, Production Supervisor Linda Shaw was politely interrupted by Tammie, a member of the Production team.

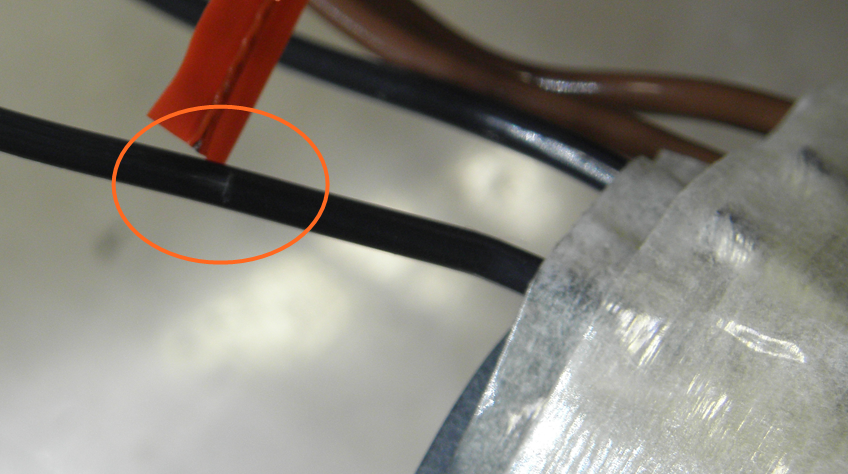

Tammie was concerned that a very slight nick in the lead-wire insulation for an assembled hardware component should be replaced. Linda looked closely at the lead wire, agreed with Tammie that it should be replaced, and said “Yes, [customer name] would not like this. I’ll replace the wire and take it to the Testing Department when I’m done.”

To an outsider, the nick was barely visible. To both Tammie and Linda, it was enough to keep the transformer from passing mechanical inspection.

“As a part of this company, we have learned to care about our customer’s needs and make sure we complete our orders on a timely basis and with the utmost quality. We also have established good communication with both our customers and employees.”

Later that day, after replacing the lead-wire and considering the initial question, Linda was able to offer some insightful comments.

“As a part of this company, we have learned to care about our customer’s needs and make sure we complete our orders on a timely basis and with the utmost quality. We also have established good communication with both our customers and employees.”

When asked about STC president Brad Cross, Linda continues.

“He has been a very good leader because he works hard to operate a successful company. He listens and works with staff and employees alike to make sure everyone knows they are an important part of the company.”

Perhaps Tammie and Linda’s action earlier that day are the most telling reason for why STC remains an industry leader when it comes to high-reliability electronic manufacturing services.